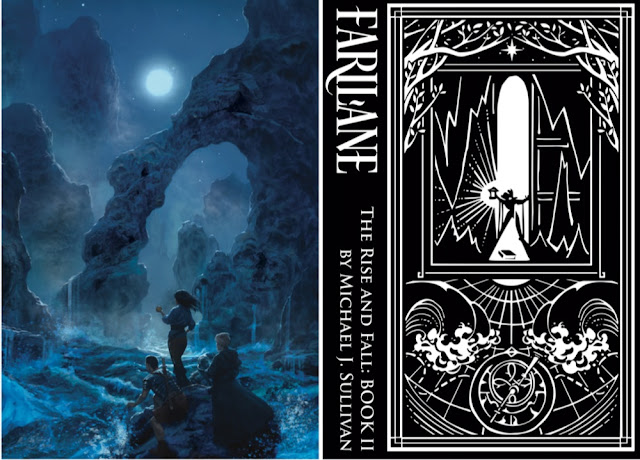

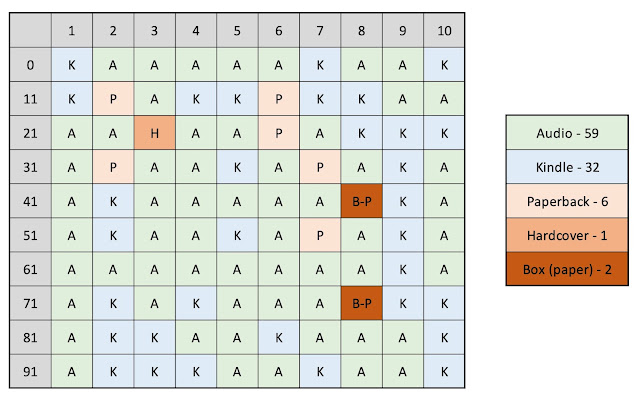

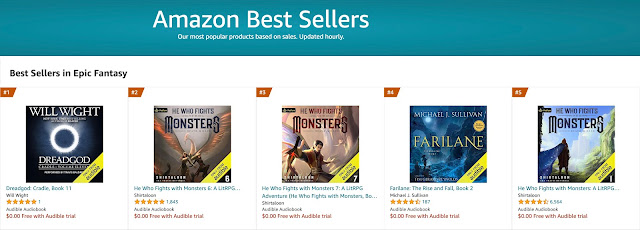

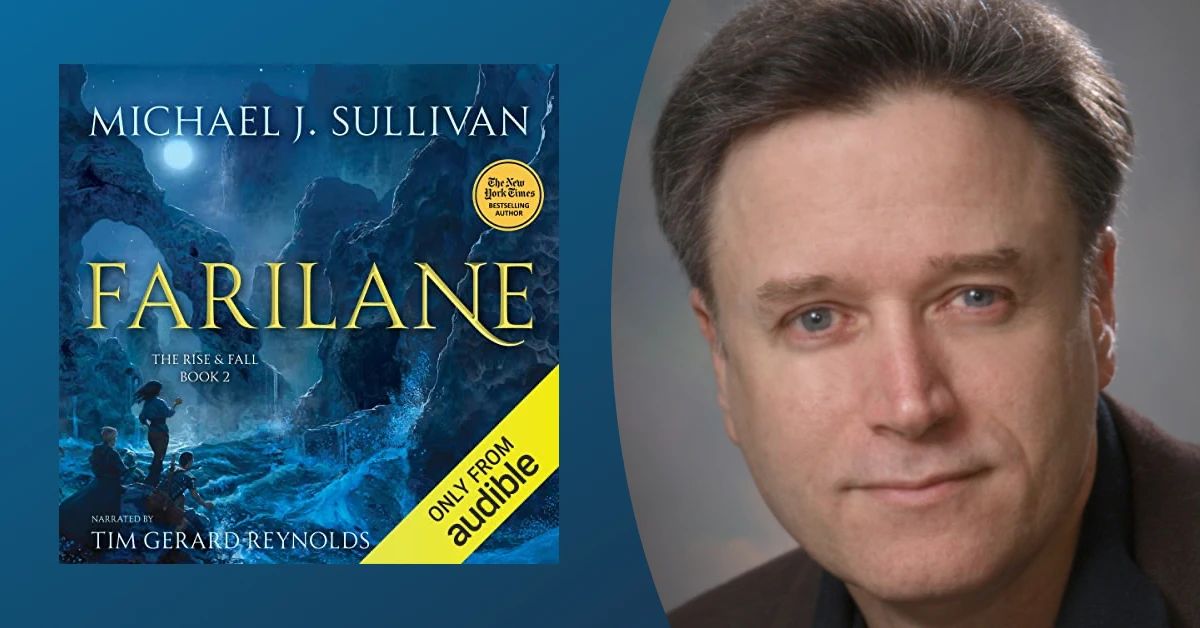

Well, it's been a little over two weeks since Farilane's ebook and audiobook were released, and we've been getting a lot of emails about when the printed books will start shipping. I guess it's time for an update on that. Let me start by stealing a bit from my wife's post on the Farilane Kickstarter.

To fully explain this I have to talk a bit about the state of printing in 2022. Back when we started printing books there were many options for printing (well maybe not "many" but certainly more than there are now. But over the last decade, a lot has happened.

- Many publishers either went out of business altogether or at least filed for Chapter 11

- One printing organization has "gobbled up" many of the remaining smaller printers.

- Publishers delayed a number of book releases during the pandemic such that the publishers have long "wait queues" that new titles have to wait in before they can get on the press.

- There is only one binder in the entire United States that can do "hubbed spines" and they do a lot of other "premier binding" work so they are quite busy.

Okay, so in late April the book was pretty much done (we were still gathering names for the Kickstarter Backer area) but we knew how many pages the book would wind up at so we could get printer quotes - let's go!

- Printer #1 - who has printed Age of Legend, Age of Death, Age of Empyre, and Nolyn. Came in with a price about 70% higher than I've had to pay in the past, which is a bummer but the real problem was the earliest press time they had was November 4th. And that date is heavily dependent on paper availability - which is something they have been struggling with a great deal.

- Printer #2 - bought up the printer that created the Death of Dulgath and The Disappearance of Winter's Daughter. Their first quote was astronomical. So they tried "running" the numbers from a different plant that "might be a better fit" and they got better, but still about 50% more than I usually pay. Their "wait time" was better - 60 days, but the special binding would be harder to predict as the one and only binder who pretty swamped so its almost impossible to know until after the books are printed and shipped to them how long they will be sitting and waiting.

- Printer #3 - I've never used them for printing and binding a book - but I have had dust jackets printed from them. They wouldn't even quote a "full book" production because their queue is just too long and until they get some of their current jobs in.

Okay, so none of those are good options, but I had been contacted by an offshore printer who looked promising. Not only could they do the hubbed spines "in-house" but being in the country where the paper is manufactured means that paper supply isn't nearly as big of a problem as it is for the US companies. But I worried about the quality. The good news, is the company was willing to create samples using the exact stock that the books would ultimately be created in. So I thought, let's give it a try.

Now things like the dust jacket and the foil stamps for the spine of the book can't be made until the printer is selected because the "width of the spine" will depend on the paper used. I also wanted to do some "upgrading" (using higher-end papers) because that would help ensure a higher quality book, and if "low quality" was a concern (which it was for Robin), we might as well use "the good stuff" in the hopes of getting a better product.

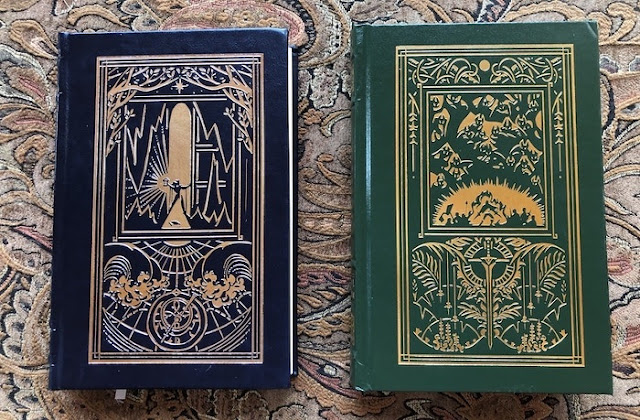

So, while the samples were being made and shipped to us Robin and I went off to our long-planned vacation of white-water rafting down the Colorado River at the bottom of the Grand Canyon. After we hiked our way out and flew back home on June 6th the samples arrived the next day. And here they are!

The quality was excellent! Even better than what I've received from the other printers I've used previously. And since they could get on and off the press in a fraction of the time as the other printers it made total sense to add this new printer to my list of places I can go to for books. So that's exactly what we did!

Now switching printers did result in a little bit of a delay because we had to layout the book a bit differently. Why? Well, these books are "Smyth sewn" rather than "adhesive bound." A sewn book is always better than a glued book and they have the added benefit of "laying flat" when you read them. When you layout an adhesive-bound book you leave a larger margin on the right side of the left-hand page and the left side of the right-hand page. In other words, you leave "more space" near the spine. And because we had intended to do adhesive-bound books, that is the way our original layout was. But when looking at the sample, that extra space wasn't needed so we had to move everything a bit. This took us about a week to do and proof, but it was time well spent to get a higher-quality binding.

So, the books are due to come off the press on July 25th. Once they are done, they have to ship to us, and that will take longer than shipping within the US. But even with that extra step, we will get them earlier than printer #2 would have been able to deliver and MUCH earlier than printer #1.

We'll be back with more updates as they get closer to us. If you want to get the books as fast as you possibly can, I suggest buying them directly from us. Here's why.

- Right now, our store is the ONLY place you can do a pre-order. The pre-order for the stores won't go live until we can guarantee our distributors when they'll have books in hand and then they usually set the pre-order date about 60 days after they have the books.

- Both our warehouse and the distributor's warehouse will get the books at essentially the same time, but we can ship ours as soon as they are in hand and the "retail books" have to get "checked in" at the main distributor, then he pre-orders have to be made, and THEN the books start traveling to the retailer's warehosues and they have to get checked in there And only after that can they start fulfilling their pre-orders

- All books bought from me will be signed!

- All books bought from me will have a matching bookmark (also signed)!

- When buying retail, approximately 80% of the amount you pay goes to other people: the printer, the distributor, and the retailer. When you buy direct that goes down to about 10% because all we have to pay for is the printer, the credit card company, and pay the labor to package and ship the books. So if you would rather have 90% come to the writer of the tale rather than 20% - then please buy direct!

And that's where we stand. I can't wait for people to start receiving these beautiful books. But supply chain issues are a big problem right now - and probably will be for some time to come.